[01]

2025

Project

[Design]

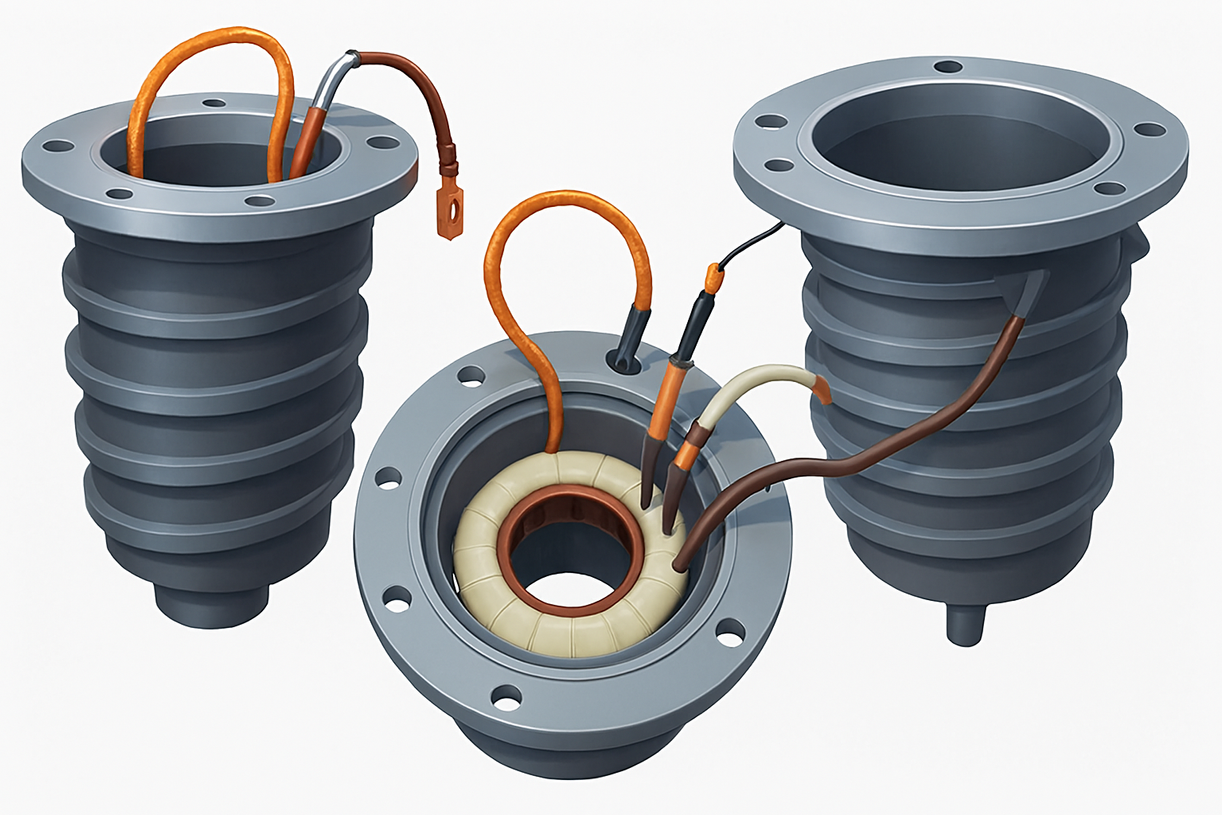

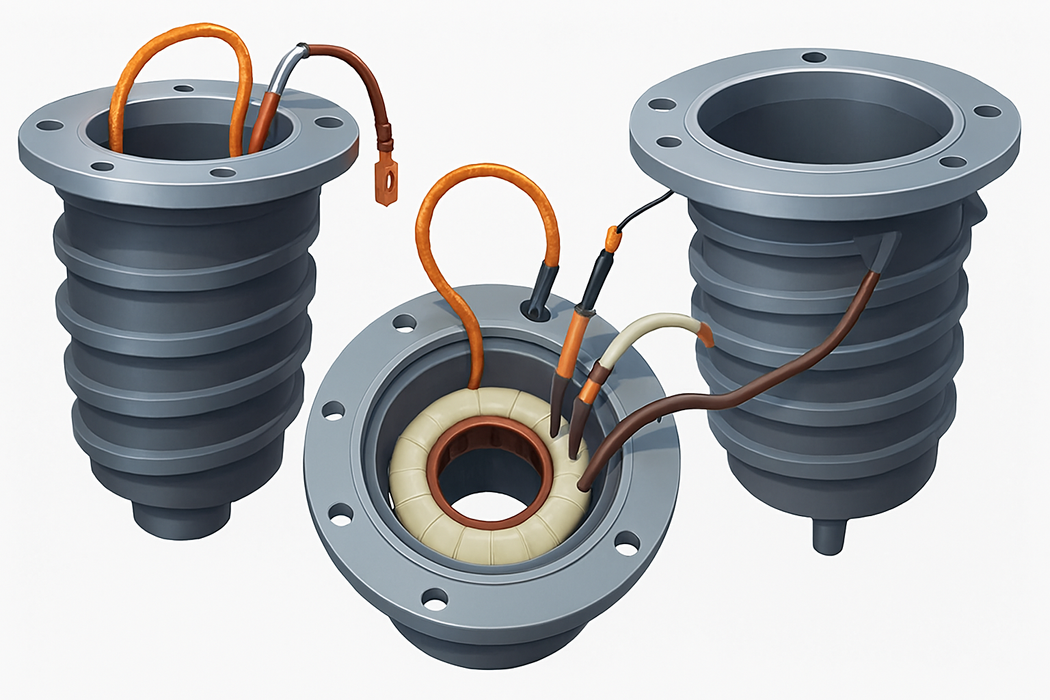

Assembled Motor View

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

[01]

2025

Project

[Design]

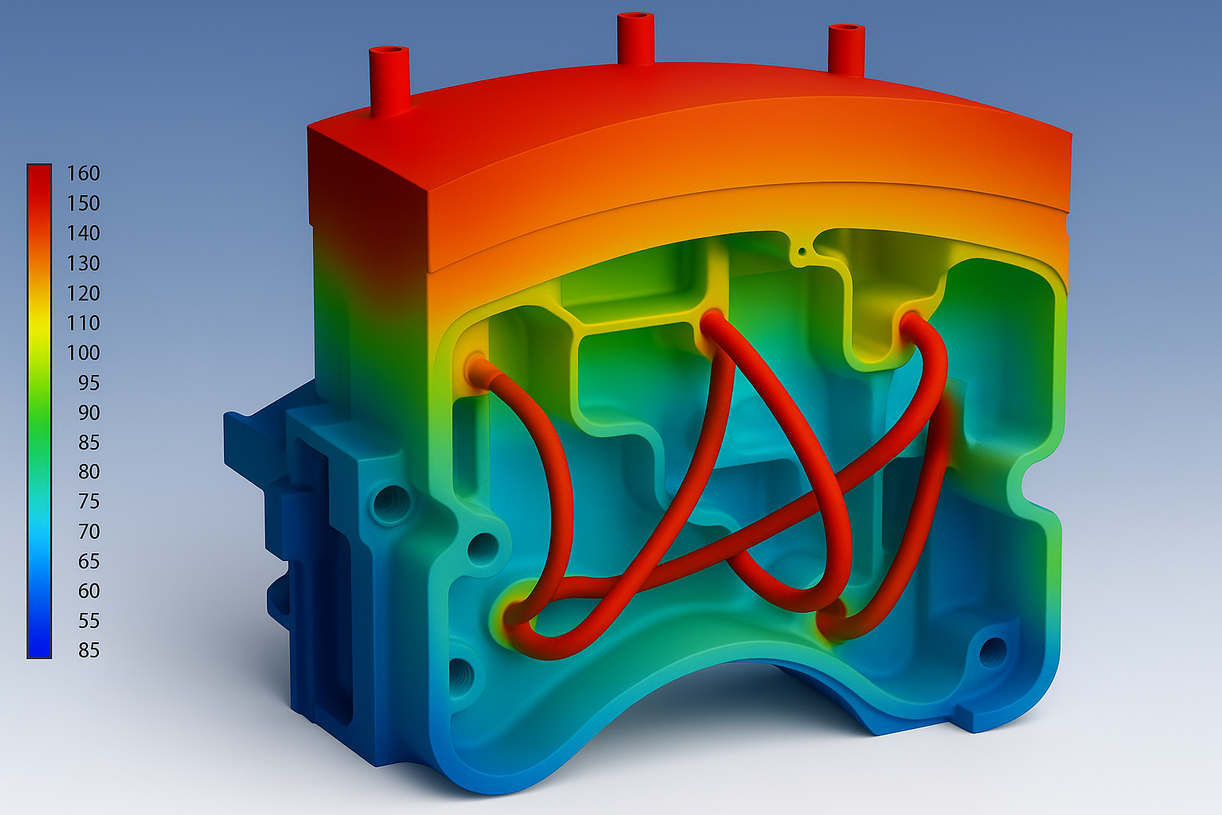

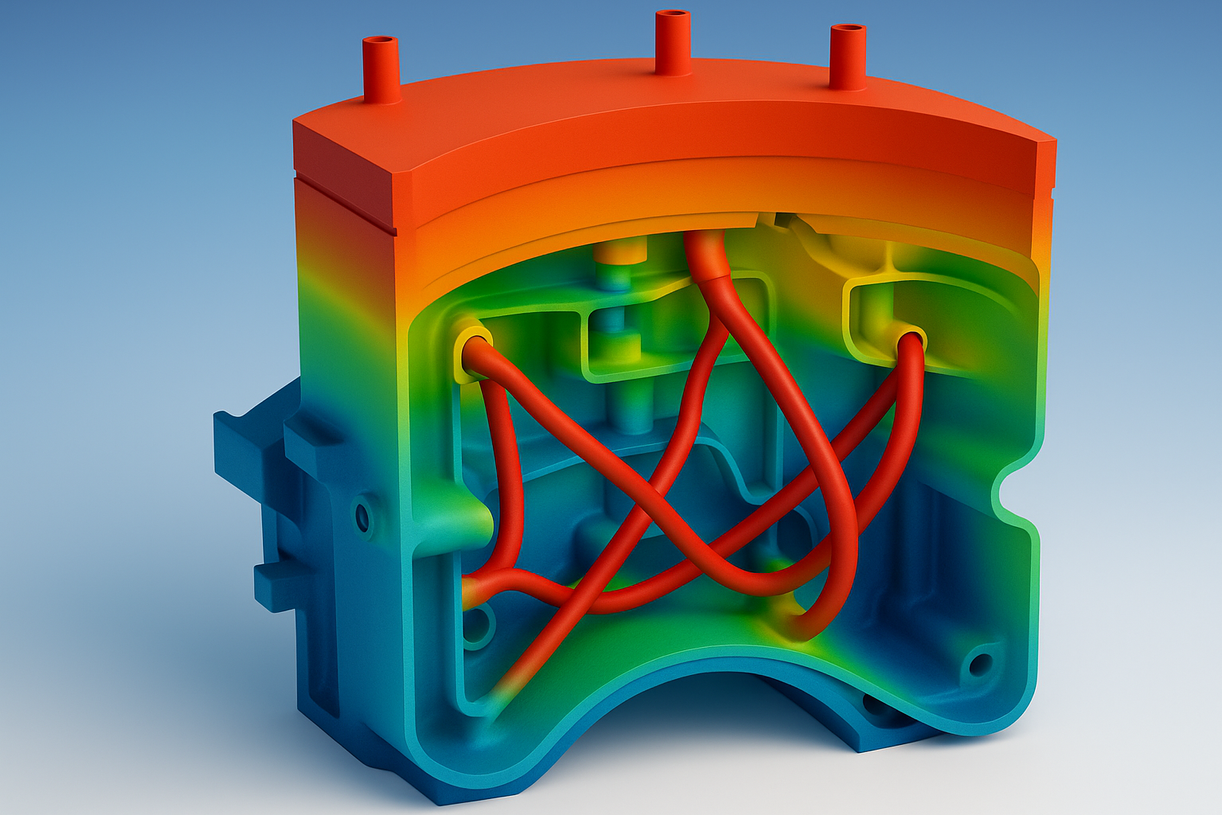

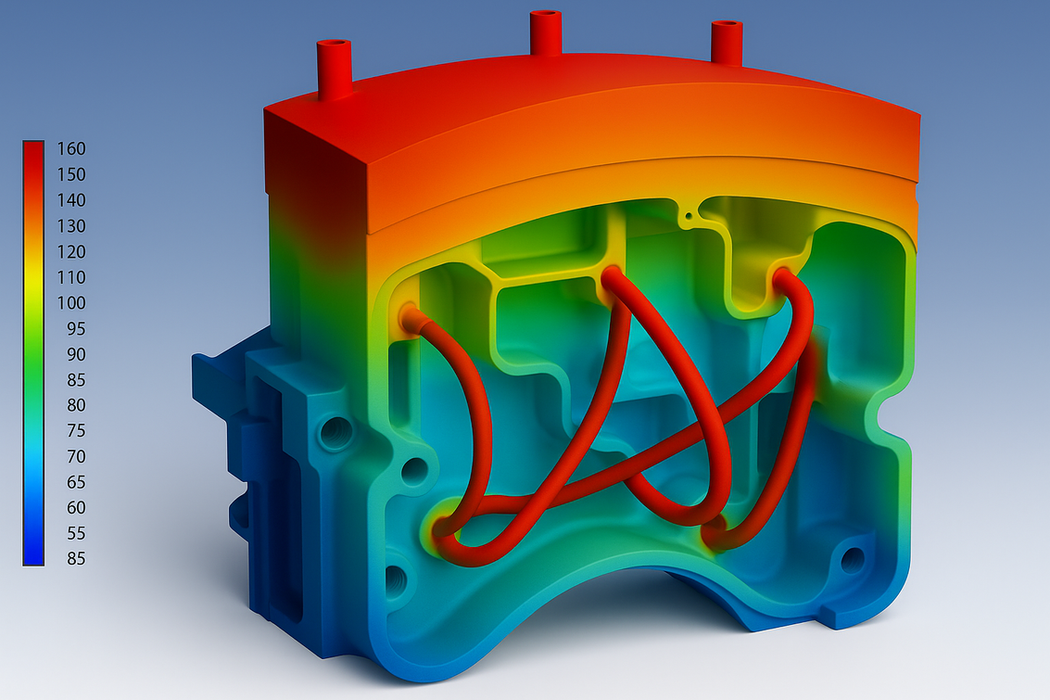

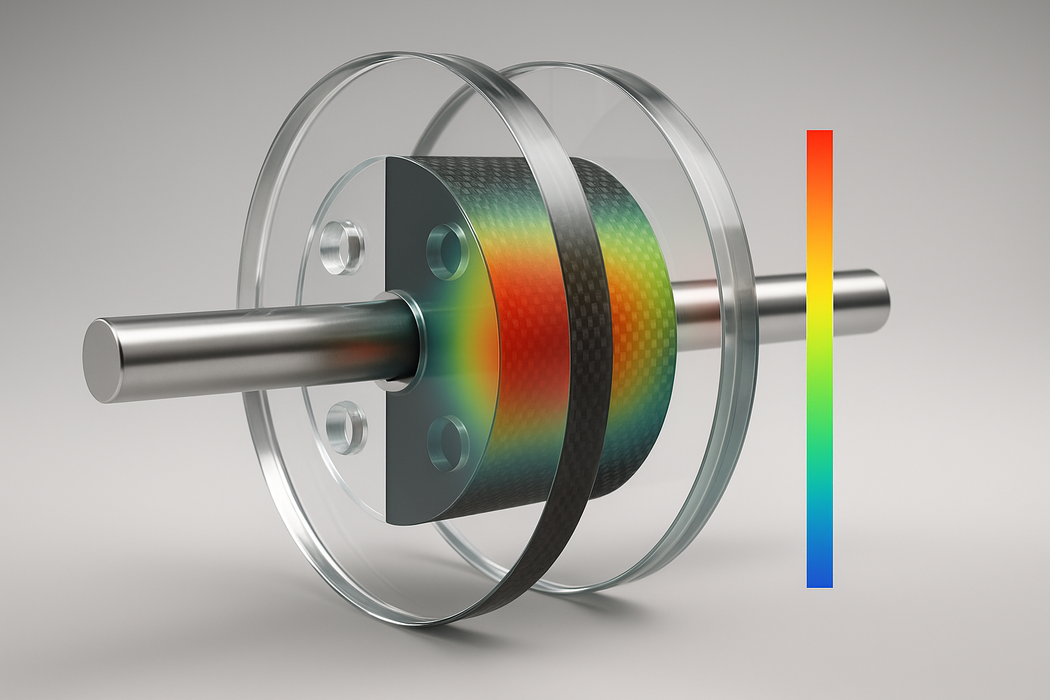

Thermal Gradient simulation across cable housing

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

[01]

2025

Project

[Design]

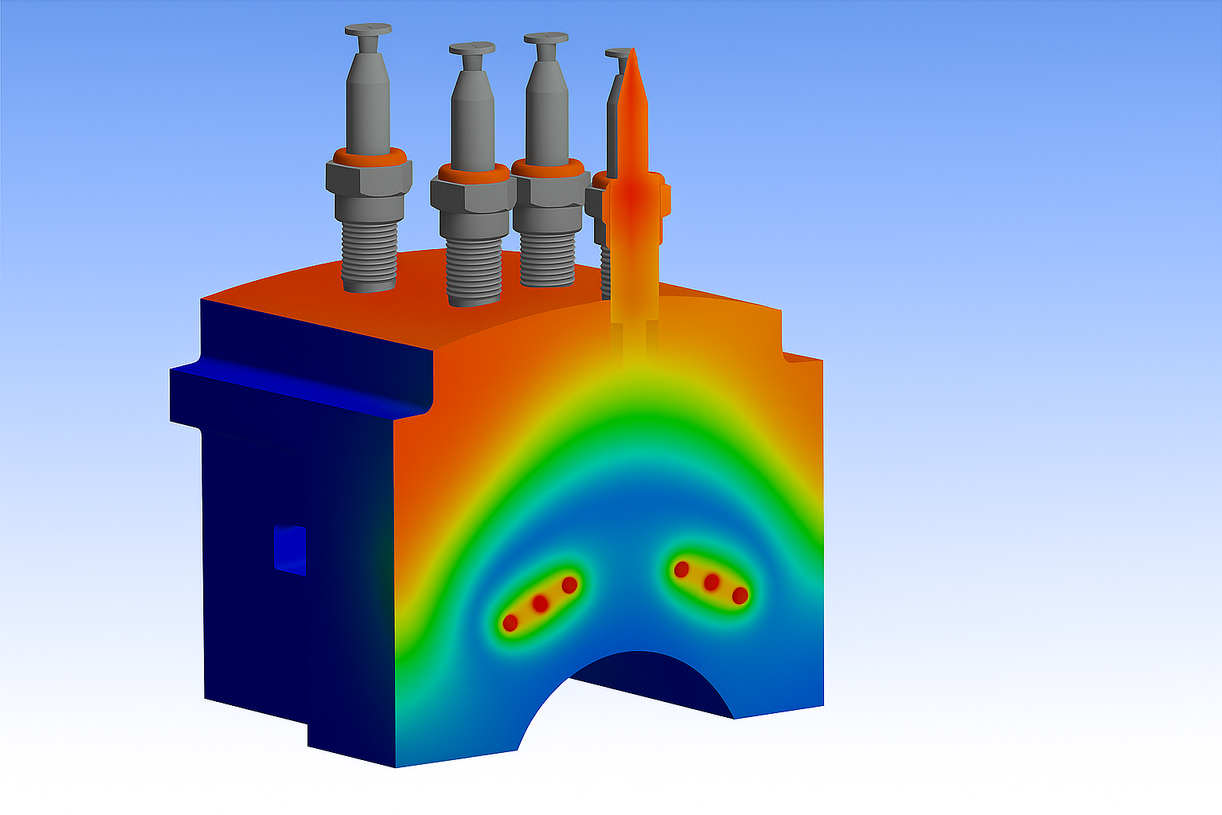

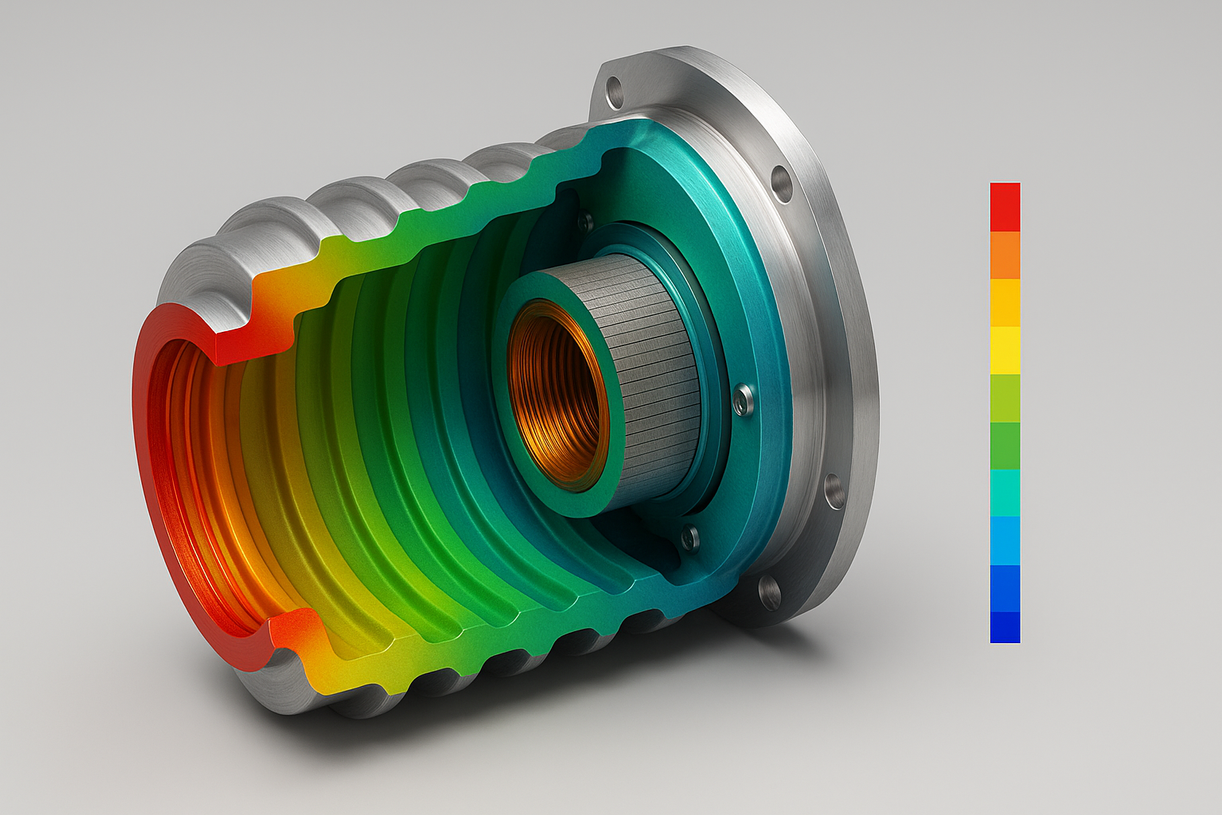

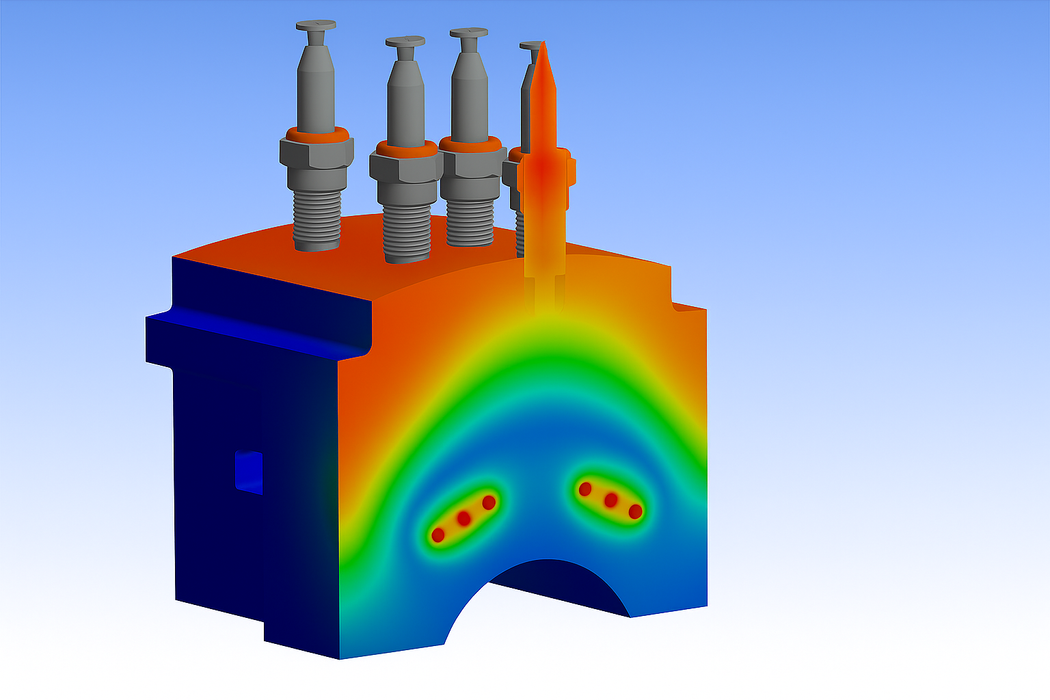

Alternator Thermal Simulation

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

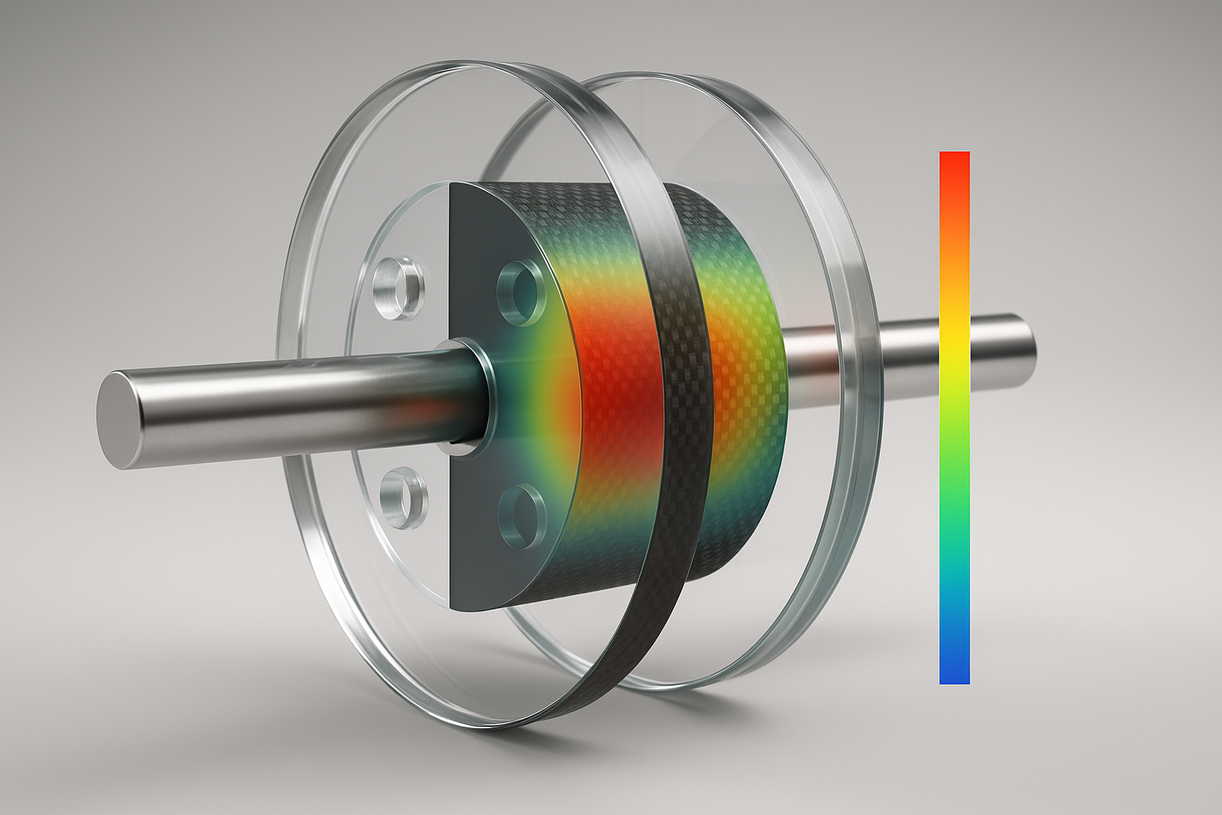

Multi-Physics Model Simulation and Validation

[01]

2025

Project

[Design]

Range of Visal Facets and Variations of Project.

Illustrative concept to demonstrate methods; parameters are intentionally generic. Any resemblance to real designs is coincidental. Content policy: T&Cs.

Multi-Physics Modeling for Thermal and Structural Validation

Advance a rigorous multi‑physics workflow that validates the thermal and structural integrity of an electric turbo‑charger power assembly, spanning electro‑thermal loading, cooling performance, and mechanical stress limits.

Working Details

Phase 1: Model Scoping & Baseline Analysis: Established the analytical framework for a critical electric turbo-charger sub-assembly, defining the boundary conditions and preparing the CAD geometry for a multi-physics environment.

Phase 2: Electro-Thermal Simulation: Developed a detailed thermal model to simulate the Joule heating effect resulting from a continuous 265 A, 3-phase electrical load, accurately predicting heat generation within the conductors.

Phase 3: Conjugate Heat Transfer (CHT) Analysis: Executed a comprehensive fluid dynamics simulation (Fluent/CFX) to characterize the heat rejection capabilities of the integrated fluid-cooling circuit, quantifying the heat transfer between the solid components and the coolant.

Phase 4: Coupled-Field Integration: Mapped electro‑thermal and CFD results to deliver a comprehensive temperature field for structural assessment.

Phase 5: Thermomechanical Structural Assessment: Performed high‑fidelity static analysis including thermal contact resistance and potting behavior to evaluate stresses and deflections.

Phase 6: Validation and Verification: Executed mesh‑convergence studies and benchmarked predictions against test data, confirming insulation temperatures and mechanical stresses within design limits.

Tools and Skillset

Ansys Workbench (Thermal, Structural, Fluent/CFX)

Coupled‑field setup & Joule heating mapping

Thermal contact & potting modelling

Conjugate heat‑transfer analysis

Mesh convergence & result validation

Comparative material selection

Technical reporting & cross‑disciplinary collaboration